CUTTING, BEVELLING

Pipe cutting and Bevelling machine

The only beveling machine designed with the end users based on their know-how

DWT offers equipment for beveling thick pipes with a historical know-how from the technicians working on site with these machines. DWT GmbH in Essen, Germany manufactures equipment for the preparation and chamfering of pipes before welding, used for thick-walled pipes, boiler pipe panels and water-cooled walls. Pipe preparation is the first and most important step in the process before welding. Especially for thick-walled pipes, the pre-weld preparation bevel must be perfect to obtain the quality welding result. We offer a unique product range for the needs of the international pipe installation industry, where the materials to be processed are becoming more and more sophisticated. Nowadays the increase in thickness and the steels are more and more difficult to machine. Our beveling machines can meet the needs of the modern world regardless of thickness and material. The portable machines are lightweight so that they can be handled by one man in different job site configurations.

Advantages

The range of equipment for the preparation and chamfering of tubes before welding is efficient and very competitive due to the following advantages:

Lightweight due to its aluminium design, quick and safe installation, internal and external clamping, powerful, robust and compact, easy and safe to use, very flexible and versatile for pre-weld preparation; perfect beveling quality.

Quick adjustment, powerful and robust, maximum productivity, maximum quality, ergonomic, quiet, no dust, high reproducibility, high quality tools, powerful motor, long service life.

- MF3IW Outer tube Ø: 25mm to 96 mm

- MF5I Outer tube Ø: 100mm to 380mm

- MF4 Outer tube Ø: 25mm to 133mm

- MF3-R Outer tube Ø: 9mm to 44.5mm

- MF4R Outer tube Ø: 30mm to 88.9mm

- MF2-25 Outer tube Ø: 8mm to 38mm

- MF3-25 Outer tube Ø: 12.5mm to 63.5mm

- MF3-25XL Outer tube Ø: 12.5mm to 76.1mm

- MF2IW Outer tube Ø: 11mm to 22mm

- MF3I Outer tube Ø: 40mm to 152mm

- MF4I Outer tube Ø: 58mm to 217mm

- MF6I-50 Outer tube Ø: 280mm to 700mm

Pipe beveling machine MF2iw

The pipe beveling machine MF2iw is used for the preparation of pipes before welding. It is used for boiler tube panels, to cut and bevel these tubes. The MF2iw is equipped with a pneumatic motor placed at 90°. The clamping is done by a knurled wheel and the feed is done by a lever.

Technical characteristics :

Clamping range ID-OD : 11 – 28 mm

ID-ID working range: 11 – 22 mm

Max. pipe wall thickness: 3 mm

Weld shape: 0° machining, V weld

Feed: 20 mm

Engine: Pneumatic

Pipe beveling machine MF3iw

The MF3iw pipe beveling machine is used for the preparation of pipes before welding. It is used for boiler pipe panels, to cut and bevel these pipes. The MF3iw is equipped with a pneumatic motor placed at 90°. It can be equipped with air motor or electric motor. The clamping device is made by a lever, the feed of the tool can be controlled by a lever or a knob. All pipe beveling machines can be easily equipped with either pneumatic or electric motor, clamping and feed by lever or knurled wheel.

Technical characteristics :

Clamping range ID-OD: 25 – 101,4 mm

ID-ID working range: 25 – 96 mm

Max. pipe wall thickness: max. 15 mm

Weld shape: 0° machining, V weld, splintering

Feed: 20 mm

Engine: Pneumatic / Electric

Pipe chamfering machine MF3i

The MF3i prepares tubes before welding, single tubes or boiler tube panels, for cutting such as chamfering. The machine can be motorized either pneumatically or electrically. As standard the machine is configured with the right motor, in line with the body of the machine but on request the motor can be installed at 90°. The clamping can be done by a lever or pawl, and the feeding by a knurled wheel. A version is available with removable ratchet.

Technical characteristics :

Clamping range ID-OD: 27 – 160 mm

ID-ID working range: 40 – 152 mm

Max. pipe wall thickness: max. 25 mm

Weld shape: 0° machining, V weld, splintering

Feed: 15 mm

Engine: Pneumatic / Electric

Pipe chamfering machine MF4i

The MF4i prepares tubes before welding, single tubes or boiler tube panels, for cutting as well as beveling. The machine is equipped with 2 pneumatic motors. The clamping is done by a handwheel and the advance by a knurled wheel.

Technical characteristics :

Clamping range ID-OD: 58 – 219.1 mm

Working range ID-ID: 58- 217 mm

Max. pipe wall thickness: max. 25 mm

Weld shape: 0° machining, V weld, splintering

Feed: 30 mm

Engine: Pneumatic

Pipe beveling machine MF5i

The MF5i prepares tubes before welding, individual tubes or boiler tube panels, for cutting such as beveling. The machine is equipped with 2 pneumatic motors. The clamping is done by a handwheel and the advance is done by a knurled wheel.

Technical characteristics :

Clamping range ID-OD: 100 – 332 mm (Extension XL min OD 460 mm)

ID-ID working range: 100 – 380 mm (XL extension min ID 176 mm)

Max. pipe wall thickness: max. 30 mm

Weld shape: 0° machining, V weld, splintering

Feed: 30 mm

Engine: Pneumatic / Electric / Hydraulic

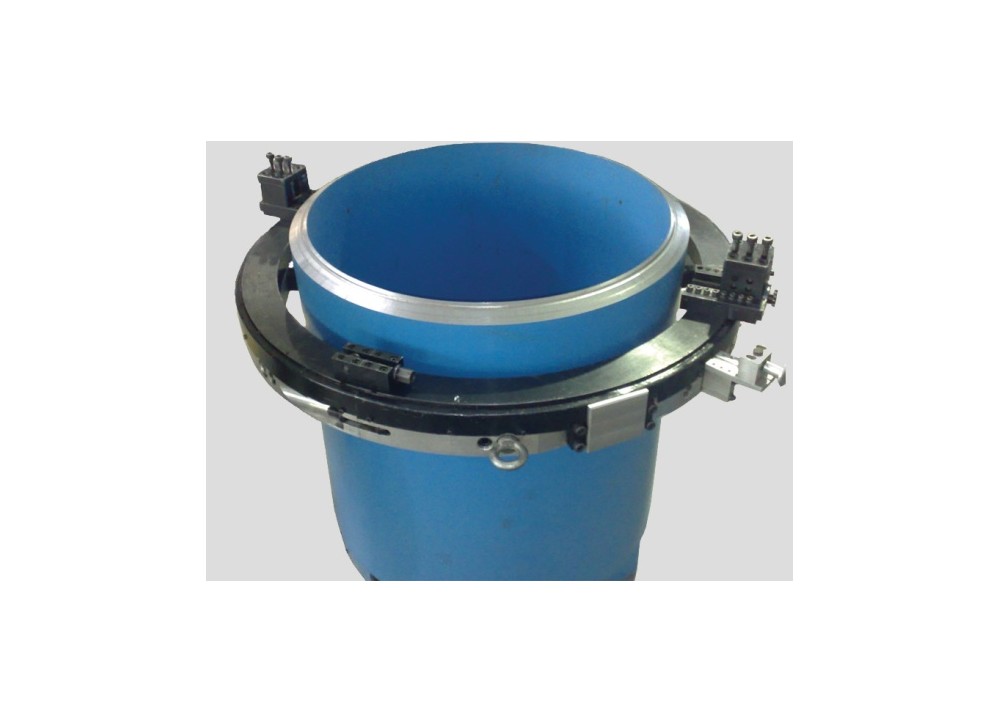

Pipe beveling machine MF6i-50

The MF6i -50 performs the preparation of tubes before welding, individual tubes or boiler tube panels, for cutting such as beveling. The machine is equipped with 3 pneumatic motors or 2 hydraulic motors. The clamping is done by a handwheel and the advance is done by a knurled wheel.

Technical characteristics :

Clamping range ID-OD: 280 – 711 mm

ID-ID working range: 280 – 700 mm

Max. pipe wall thickness: max. 30 mm

Weld shape: 0° machining, V weld, splintering

Feed: 350 mm

Engine: Pneumatic / Hydraulic

Pipe beveling machine MF3-EF

Technical characteristics :

Clamping range OD-OD: 20 – 63,5 mm

ID working range: 12.5 mm

Pipe wall thickness: 10 mm

Materials: Steel, stainless steel, duplex, alloy steel

Tools: Reversible cutting inserts

Pipe beveling machine MF3-R

Technical characteristics:

Clamping range OD-OD: 12 – 44.5 mm

ID-OD working range: 9 – 44.5 mm

Pipe wall thickness: max. 10 mm

Weld shape: 0° machining, V weld

Feed: 15 mm

Motor: Pneumatic/Electric

Pipe beveling machine MF4-R

The MF4-R is used for pipe preparation, i.e. beveling pipe edges or membrane panels. Due to its small dimensions this machine is particularly suitable for the preparation inside the membrane panels. The MF3-R can optionally be equipped with a pneumatic or electric motor. The clamping is done by a lever at the front of the machine and the feeding is done by a lever at the back of the machine. In addition to its conventional use the MF3-R can also be used as a stationary machine.

Technical characteristics :

Clamping range OD-OD: 48,3 – 88,9 mm

ID-OD working range: 30 – 88.9 mm

Pipe wall thickness: max. 10 mm

Weld shape: 0° machining, V weld

Feed: 15 mm

Motor: Pneumatic/Electric

Pipe beveling machine MF2-25

The pipe beveling machine MF2-25 is used for preparing pipes, beveling pipes and membrane panels. Due to its small size it is particularly suitable for preparations inside membrane boilers. The MF 2-25 can optionally be equipped with a pneumatic or electric motor. The great advantage of this machine is that it can be used on panels with diameters of Ø 20mm and with a specific tool, a crown that will allow the beveling of the tubes of the panel and the machining of the steel between tubes. The minimum width of the membrane panel is only 40,0mm!

Technical characteristics :

Clamping range OD-OD: 20 – 38 mm

ID-OD working range: 8 – 38 mm

Pipe wall thickness: max. 15 mm

Minimum width of the diaphragm wall ports: 40 mm

Weld shape: 0° machining, V weld

Feed: 25 mm

Motor: Pneumatic/Electric

Pipe beveling machine MF3-25

The pipe beveling machine MF3-25 is used for preparing pipes, beveling pipes and membrane panels. Due to its small size it is particularly suitable for preparations inside membrane boilers. The MF3-25 can optionally be equipped with a pneumatic or electric motor. It is designed with the motor and the shaft aligned, but on request it can also be supplied with an angle drive. So it can be used in difficult situations with limited space. In addition, the drive connection can be easily changed.

Technical characteristics :

Clamping range OD-OD: 20 – 63.5 mm

ID-OD working range: 12.5 – 63.5 mm

Pipe wall thickness: max. 15 mm

Minimum width of the diaphragm wall ports: 56 mm

Weld shape: 0° machining, V and U weld, splitting

Feed: 25 mm

Motor: Pneumatic/Electric

Pipe beveling machine MF3-25 XL

The MF3-25 XL pipe beveling machine is used for preparing pipes, beveling pipes and membrane panels. Due to its small size it is particularly suitable for preparations inside membrane boilers. The MF3-25 can optionally be equipped with a pneumatic or electric motor.

Technical characteristics :

Clamping range OD-OD: 20 – 76,1 mm

ID-OD working range: 12.5 – 76.1 mm

Pipe wall thickness: max. 15 mm

Weld shape: 0° machining, V and U weld, splitting

Feed: 25 mm

Motor: Pneumatic/Electric

Pipe beveling machine MF4

The MF4 pipe beveling machine is used for pipe preparation, beveling of pipes and membrane panels. Due to its small size it is particularly suitable for preparations inside membrane boilers. The MF3-25 can optionally be equipped with a pneumatic or electric motor. It is designed with the motor and shaft aligned, but on request it can also be supplied with an angle drive. Therefore, it can be used in difficult situations with limited space. In addition, the drive connection can be easily changed.

Elbow beveling machine

The portable elbow beveling machine complements our standard pipe beveling machine, which is exclusively designed for beveling the outside and inside of elbows, for both production and repair. The positioning jaws hold the machine in place and align the bend to the pipe. The dimensions of the jaws allow easy centering. With the standard jaws it is possible to install the mandrel close to the end of the pipe. With additional jaws the mandrel can be installed deeper for beveling the inside.

Bend beveling machine for MF3i

TE43 is the smallest pipe beveling machine thanks to the replacement of the standard axis of the MF3I pipe beveling machine with a special mandrel. All legs adjust at the same time when clamping. An alignment tool is used to ensure that the machine is positioned straight. For best results the machine should be clamped as close as possible to the end of the bend where the straightest part is located.

Technical Details / Advantages :

Chuck dimensions for OD bend: 1.69″. (43 mm)

ID-ID clamping range: 1.69″ – 4.17″ (43 – 106 mm)

OD-OD working range: 2″ – 4″ (60.5 – 114 mm)

Comes with :

Chuck for elbow

Clamping feet for all diameters, which do not damage the tube

Liners for easy adjustment

Tools for installation

Storage case

Elbow beveling machine TE80

The elbow beveling machine is designed on the same principle as the standard machines; the mandrel is installed in the elbow via feet on the inside of the elbow. Each foot can be adjusted individually for easy centering. The legs have a swivel head to protect the inner surface of the pipe when clamping the pipe.

Elbow beveling machine for MF4i

The mandarin for elbow TE120 is made for the MF4I beveling machine and works on the same principle : the mandrel is installed in the elbow via feet inside the elbow. Each foot can be adjusted individually for easy centering. The legs have a swivel head to protect the inner surface of the pipe when clamping the pipe.

Technical Details / Advantages :

Chuck dimensions for ID elbow: 3.07″ (78 mm)

Chuck dimensions for OD elbow: 4.48″ (114 mm)

ID-ID clamping range: 4.88″ – 7.99″ (124 – 203 mm)

OD-OD working range: 6″ – 8″ (168.1 – 219 mm)

Comes with :

Elbow chuck, clamping feet for all diameters, which does not damage the tube, liners for easy adjustment, installation tools, storage case.

Para MF5i Para elbow beveling machine

Elbow beveling machine TE160

This elbow mandrel for beveling machine MF5I works on the same principle; the mandrel is installed in the elbow via feet inside the elbow. Each foot can be adjusted individually for easy centering. The legs have a swivel head to protect the inner surface of the pipe when clamping the pipe.

Technical Details / Advantages :

Chuck dimensions for elbow ID: 4.92″. (125 mm)

Chuck dimensions for OD elbow: 6.29″ (160 mm)

ID-ID clamping range: 8.50 – 12.20″ (216 – 310 mm)

OD-OD working range: 10″ – 12″ (273 – 332 mm)

Comes with :

Elbow chuck, clamping feet for all diameters, which does not damage the pipe, liners for easy adjustment, installation tools, storage case.

We remain at your disposal for any need in orbital cutting machines.

- In permanent search of innovations, we propose you with Exact Tools precise, fast and effortless solutions for cutting and finishing your tubes and pipes. These portable machines are suitable for all types of materials. Each unit cuts a range of diameters, increasing operator safety and saving time compared to traditional tools. Ergonomically designed, Exact Tools ® tube and bevel cuts greatly reduce the risk of accidents.

- Exact PipeCut 170, 170E, 170 Battery

- Exact PipeCut Bevel 170E

- Exact PipeCut 220E

- Exact PipeCut 280E

- Exact PipeCut 360R

- Exact PipeCut 410E

- Exact PipeCut P400, P400 Battery

- Exact PipeCutV1000, V1000 Battery

- Exact PipeBevel 220E, 360E

- Consumables : Blades (TCT, Cermet, Diamond, Diamond Cut Bevel),

- Accessories : Pipe support, Work table, Pipe Bench, etc..

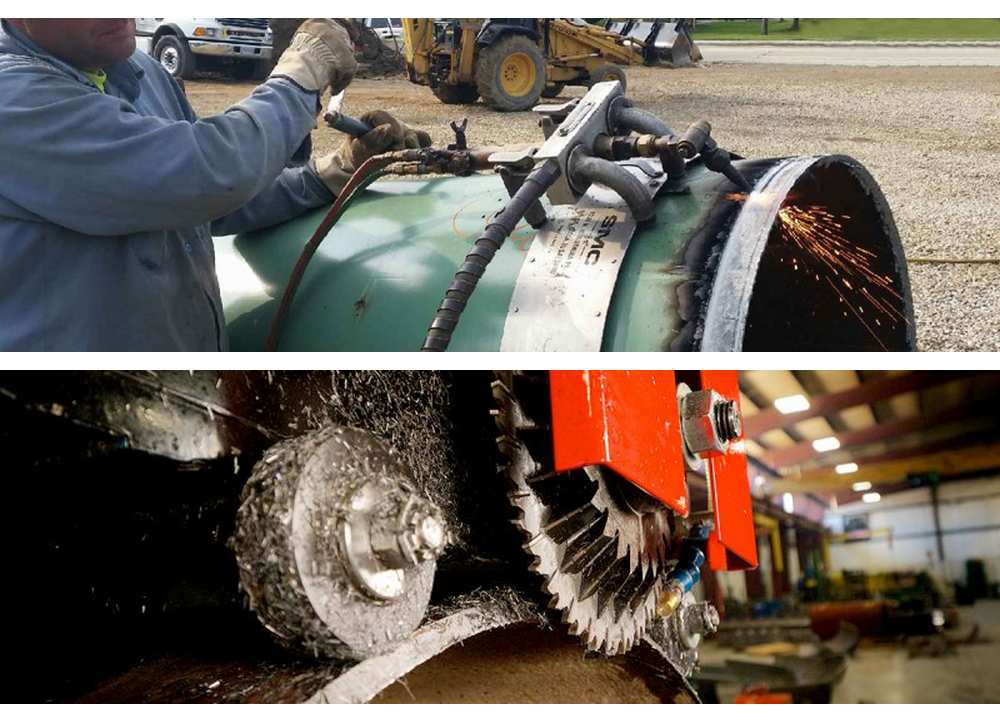

For the cut and beveling simultaneously of pipes out of steel.

- All machines are made so that they can be assembled in the middle of a pipe or section. The fixing of the machine is done by a fast locking.

- The blowtorch carriage is controlled by two cranks and four driving wheels. The cranks are placed so that the operator does not need to change their position during the cut of the pipe.

- Instead of the hand drive control, an electric drive with spur gear and adjustment of uninterrupted turns/minute can be provided. The blowtorch can swivel 2 X 45°. Moreover the blowtorch can be regulated laterally and in height by two toothed racks.

The design of the beveling machines is different according to the size:

- Model 0: half collar and a swiveling arm.

- Model 1 to 3: two half collars which open.

- Model 4: with guidance by steel band.

For cutting steel tubes with acetylene or propane torches.

- Bevel cut on horizontal or vertical tube (with optional guide) n manual version by means of two cranks or a remote flexible control (optional)or motorized by a low voltage motor with a remote control box and speed adjustment. Adjustable torch holder. Double link chain.

- Bevelling cutting machine very precise, weighing only 9 kg, this small rugged unit offers simple maintenance, easy operation and true maneuverability. With its chain guide system, the Picle-1 solves all circumferential cutting problems. This machine is easily transportable from one workstation to another, it can be used both on a construction site and in a workshop, for straight cuts and chamfers on tubes of different diameters and thicknesses.

MSA, 1SA, 2SA, 3SA, 4SA, 5SA, 6SA, 7SA, 8SA

Reliable and precise saddle machines are designed specifically for the applications which require a high degree of quality of cut and accuracy.

The machines are available for sizes of pipe from 1 1⁄2 ” to 48″ (38-1219mm). The 1SA, 2SA and 3SA are equipped with spacers. . They can be equipped with optional of support for twinned torches, cut contours and a template (the various guides of cut are assembled easily on the cut contour). The torch follows with precision the model of guide chosen to cross and chamfer. The guides are provided on request.

Beveling machines

- For manual or motorized oxyacetylene cut, adaptable for plasma cut. Used on gas and pipeline building sites, for an optimal quality of cut.

- As standard, equipped with blowtorch and Victor torch.

- The flexible stainless bands have a width of 6″ (15,24 cm).

- The range of band goes from 6″ to 60″ (15,24 to 152,4 cm) with increments of 2″.

- Simple and easy assembling thanks to the guiding band.

Precise fixing thanks to a fast tightening device.

Very high precision of guidance and cut thanks to the broad bearing surface and notched driving wheel.

Possibility of a chamfer up to 45° using a scale of angles fixed to the blowtorch.

The machine is provided with:

- Set of 3 – 50 mm tips for acetylene.

- Set of tip borers in case.

- Adjustable wrenches

Magnacut : magnetic system of cut. Fixing on pipe: permanent magnet.

-Installation: 1 min.

- Outside Ø capacity: 6” – 168.3 mm and +.

- Inside Ø capacity: 24” – 609.5 mm and +.

- Vertical and horizontal cut.

- Cutting speed: from 51 to 813 mm/min.

- Motorization: 100 Volt DC / 24 Volt DC.

- Battery supply: 110 VAC or 230 VAC 50/60Hz.

- Weight: 16.7 kg.

- Dimension: 552.4 X 241.2 X 133.2 mm.

- Guiding rail system for vertical cut and for Ø greater than 18 18’’ .

Cutting machines

- The RSG cutting machine can be used in workshop or in building site. You make it slide around the pipe to position it. The folding model is set the same way.

- Le Coupon Cutter is a rack for torch. It enable the torch to move laterally and perpendicularly to the pipe.

For cold cutting, beveling, welding preparation of any type of steel pipe.

- The ERFI Milling machine is dedicated particularly for cutting /bevelling for construction, repair, maintenance, of oil & gas pipelines, oil refineries and petrochemicals, as well as electric factories and distribution stations. energy. Its main quality is to be able to cut and bevel all kinds of tubes even if already installed.

- The ERFI cold cutting machine is able to directly cut and bevel pipes with diameters ranging from 150 to 1900 mm, steel, steel alloy, stainless steel, etc….

- By means of its chain, this machine is fixed on the pipe, which it cuts and bevelling by one revolution . During this operation the machine removes 4.76 mm of metal just by its central blade. It avoids any risk of deformation or cracking of the tube and polishes the cutting bevels without altering the physical qualities of the metal.

REED ® Hinged cutter (model H), Low clearance Rotary Pipe cutters REED ® (model LCRC), Rotary pipes cutters (model RC)

- For steel, stainless, ductile iron.

- For pipes out of sandstone, cement and cast iron (model K).

- For PE et PVC (HPC4, HPC8, HPC12) equipped with guiding wheels (model PLAS).

- Composed of a torch (electrode carrier) with 3 meters beam and of a lighting scraper, provided with 3 meters cable.

To light the lance, you need:

- a battery of 12V-40Ah.

- an oxygen bottle with pressure gauge.

- a thermal electrode.

After lighting, the flame which is generated by the electrode will reach a temperature of approximately 3500°C. This flame is sufficient to pierce and cut all ferrous and nonferrous materials.